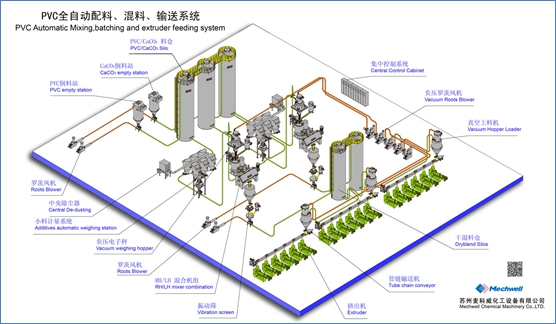

PVC Batching,Mixing and Extruders’ Feeding Plant

- PVC Batching,Mixing and Extruders’ Feeding Plant

- Material Handling System for Plastic Compounding

- Central Material Feeding System for Injection Molding and Blow Molding Machines

- Pneumatic Conveying System

- Tube Chain Conveyor System

Typical material handling plant for PVC extrusion

Raw material preparation is a necessary and very important step in a PVC extrusion process.

what is the targets we want to achieve:

A: Improve the finished product quality

(and as a consequence the profit margins of the product) Definition of quality: A product is constantly produced without any variation of the specific characteristics the product need to have for fulfilling the final task of the product’s application.

B: Improve the prestige of PVC processors

With a state of the art Raw Material Handling System the ENVIROMENTAL CONDITIONS inside and outside the production plant(Dust, Noise, Steam, Smells, Vibrations) are improved easily and therefore the prestige of this industry as well as.

C: Minimize labor cost since the introduce of automation processing

A modern material handling plant for PVC processing should include below sections and units:

![]() Send raw material into the storage silos

Send raw material into the storage silos

![]() PVC and additives dosing and weighing

PVC and additives dosing and weighing

For inquiry, go to download our questionnaire

For inquiry, go to download our questionnaire